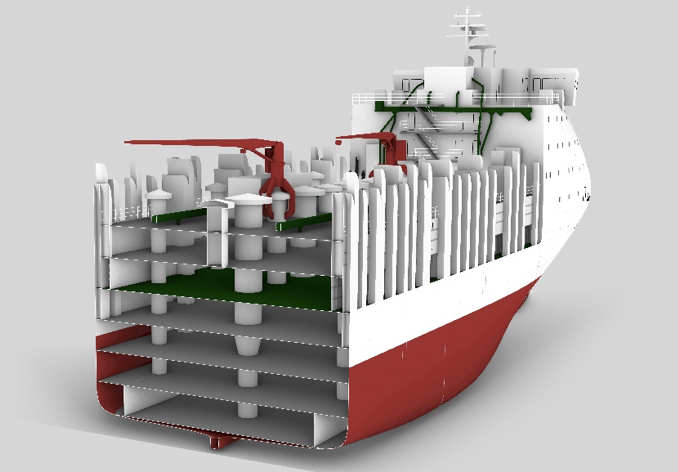

The mechanical ventilation system for the cargo area of livestock ships is a very important system that if it does not work correctly, can cause serious inconvenience to the animals, if not their death. For this reason it is always designed to assure high flow rates and this implies significant electrical loads with important repercussions on fuel consumption.

Together with Saecon, a Swiss company specialized in in CFD analysis and with a deep experience in this peculiar matter, on the basis of the results obtained in the last years on livestock ships in service through suitable measurements of air flows carried out within cargo areas, we have conceived design procedures and prepared a set of typical construction details of the ships and of the ventilation ducts (particularly the exhaust ducts), which allows to drastically reduce power requirements and, at the same time, to spread more homogeneously the air flow within the cargo area, keeping the number of air changes at the wanted target (EF > 3). Recent applications on a livestock carrier of about 5500 sqm have shown that the auxiliary power during navigation could be reduced of about 20-25% compared to conventional ventilation systems.

Interprogetti Genova has been always dealing with research works with the aim of conceiving products of interest for the reference markets and taking care to characterize the conceived devices with “effectiveness factor” (“EF”) higher than 1 as much a s possible. Click here and discover more research and development work.